About us

Metallic materials are the backbone of the manufacturing industry and metal casting, and play a pivotal role in fuelling economic growth. Metal castings are used in over 90% of all manufactured goods and in nearly all manufacturing machinery. The UK metal casting industry adds £2.6bn/year to the UK economy, employs 30,000 people and produces 1.14bnT of metal castings. It underpins the competitive position of every sector of UK manufacturing across automotive, aerospace, defence, energy and general engineering. However, the industry faces severe challenges, including having been “hollowed-out” over the past 30 years, increasing energy and material costs, tightening environmental regulations, shortage of skilled people and fierce competition from the emerging economies.

Building on the success of the EPSRC Centre – LiME, we have now established the Future Liquid Metal Engineering Hub (Future LiME Hub) to address these challenges. The core Hub activities are based within BCAST at Brunel University London and are strongly supported by the complementary expertise of our academic spokes at Oxford, Leeds and Manchester Universities and Imperial College London and with over £40M of new financial investment from our industrial partners. We have identified closed-loop recycling of metallic materials as the single greatest challenge and opportunity facing the global manufacturing industry, and from this we have co-created with our industry partners the Hub's research programme.

Within this research programme we are conducting fundamental research to deliver a nucleation centred solidification science to underpin closed-loop recycling; are carrying out applied research to develop recycling-friendly high performance metallic materials and sustainable metal processing technologies to enable closed-loop recycling; operating a comprehensive outreach programme to engage potential stakeholders to ensure the widest possible impact of our research and are embedding a centre for doctoral training in liquid metal engineering to train future leaders to deliver long lasting benefits of closed-loop recycling.

Sustainability Background

Natural resources are the foundation of our life on Earth and without these neither our economy or society can function. However, our natural resources are in severe danger of overexploitation and collapse. Due to the continued high level of resource consumption to fuel economic growth and the rapidly increasing world population, the global demand on natural resources and related pressure on our environment are steadily increasing, graphically illustrated in Figure 1.

It is a shocking fact that our cumulative consumption of natural resources over the last 60 years is greater than that over the whole of previous human history. With the rapid progression of modern science and technology, our capacity to exploit nature has reached an unprecedented level. Our annual extraction of natural resources was 40bnT in 1980 and increased to 60bnT in 2005, a staggering 50% increase. With an anticipated world population of 9.3bn in 2050, the predicted global natural resource consumption will be almost tripled (141bnT). Today, each person on the planet uses on average 22kg of natural resources per day, with that being 10kg in Africa, 14kg in Asia, 43kg in Europe and 88kg in North America. If every person on the planet were to consume resources as an average European, then we would need the resources of 2 planets now and 6 planets by 2050 to support our society and economy, visually shown in Figure 2. This level of overconsumption is obviously not sustainable. Thus, there is a compelling need for us to think differently, to follow a different consumption model, and to use our advanced science and technology to work with, rather than exploit nature.

Although manufacturing is mainly dependent on four metals (Fe, Al, Cu and Pb) in large quantity, today, virtually every stable element in the periodic table is used to take advantage of its physical and chemical properties. However, metal extraction and refining is extremely energy intensive and causes a huge negative impact on our environment. The world currently produces 50MT of Al and 2bnT of steel every year, accounting for 7-8% of the world’s total energy consumption and 8% of the total global CO2 emission. In 2007 the world produced 38MT of Al, consumed 2.2TkWh of electricity and released 861MT of CO2, which is more than 6 times the total UK annual electricity consumption (346bn kWh/year) and more than the UK’s annual CO2 emission (560MT) that year.

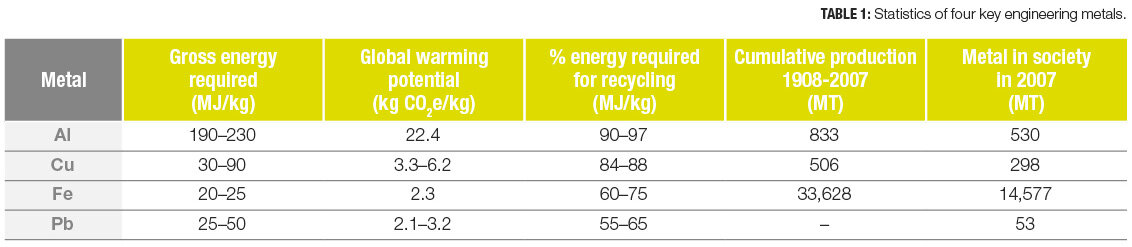

The global trend for increased metal production is predicted to continue for at least the first half of the 21st century. Clearly, we cannot continue this increasing and dissipative use of our limited natural resources. However, the good news is that metals are in principle infinitely recyclable and their recycling requires only a small fraction of the energy required for primary metal production (Table 1). Between 1908 and 2007 we produced cumulatively 833MT of Al, 506MT of Cu and 33bnT of steel. The recent estimate by the UNEP (United Nation’s Environmental Programme) is that more than 50% of these metals still exist as accessible stock in our society. Such metal stock will become our energy “bank” and rich resources for meeting our future needs. This forms the ecological basis for the vision of the Future LiME Hub.

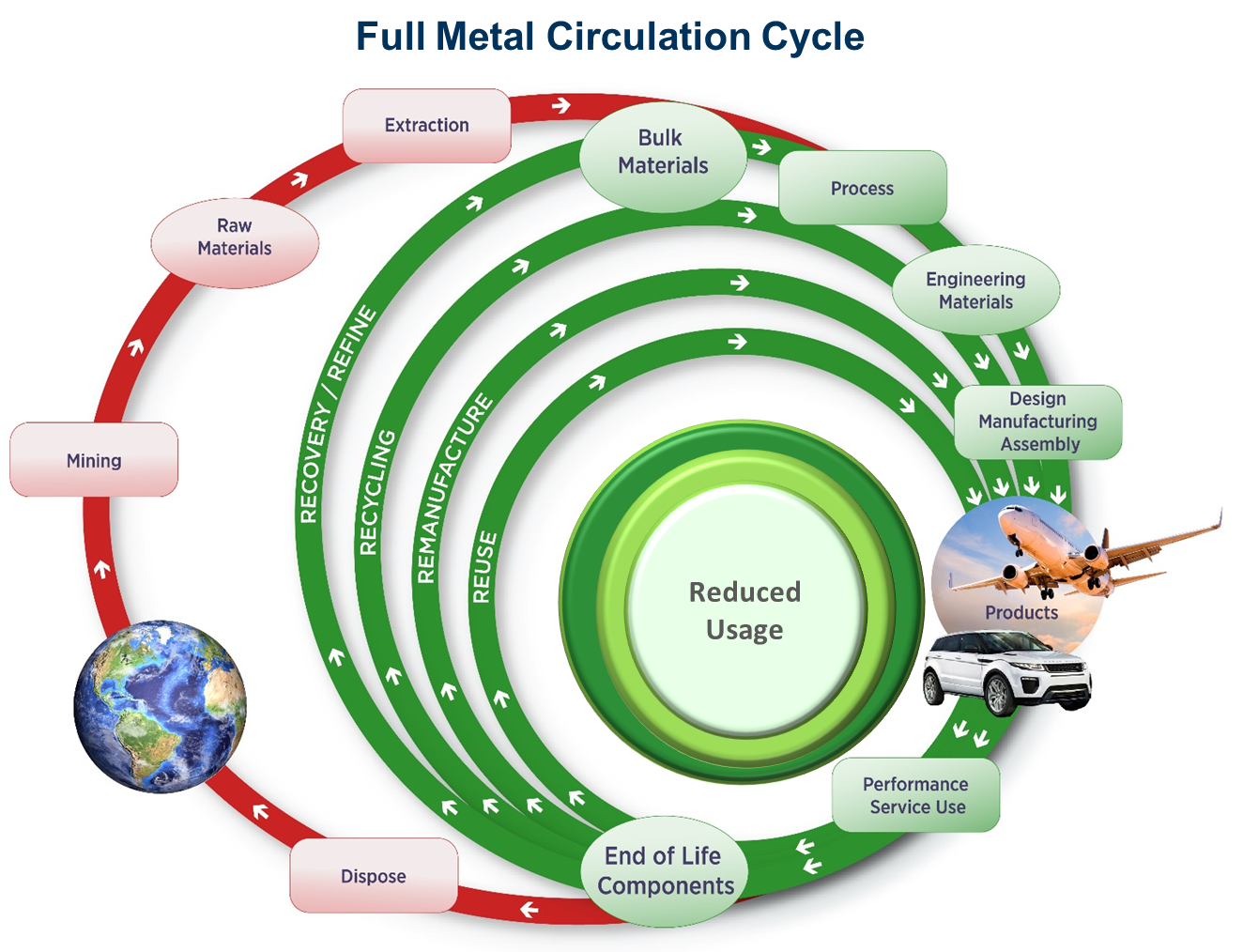

The long-term vision of the Future LiME Hub is full metal circulation, in which the global demand for metallic materials is met by a full circulation of secondary metals (with only limited addition of primary metals each year) through reduced usage, reuse, remanufacture, closed-loop recycling and effective recovery and refining of secondary metals, (as illustrated below). This represents a paradigm shift for metallurgical science, manufacturing technology and the industrial landscape. This vision is shared by both our academic spokes and our industrial collaborators. The Future LiME Hub is laying down a solid foundation for the full metal circulation concept.

Full Metal Circulation Cycle Diagram

The Future LiME Hub aims to establish the scientific basis, technological approach and industrial strategy for full metal circulation demonstrated through closed-loop recycling of light metals. More specifically, the following objectives have been set for the programme:

Remain an international leader of liquid metal engineering in fundamental research, technology development and industrial applications.

Create, deliver, disseminate and exploit a high quality and multidisciplinary research programme co-created with users to address the closed-loop recycling of metallic materials.

Be a key source for recycling-friendly advanced metallic materials, sustainable metal processing technologies and innovative industrial applications for the UK manufacturing industry and its supply chain.

Train future leaders in liquid metal engineering.

Nurture both national and international collaborations in fundamental solidification research and industrial applications.

Drive forward an extensive outreach programme to engage potential stakeholders to deliver the widest impact of the Hub’s research.

Continue to develop a growing number of academic and industrial collaborators and establish the Future LiME Hub as the leading UK resource for solidification research and technological development.

Download our latest Annual Report here.

To receive copies of previous Future LiME Hub reports or other promotional material, send us a request by email, or download here.